CML

Manual cleaning and rehabilitation | CML

The coatings in cement mortar, are mainly used to make a protective layer against corrosion.

Cement mortar coatings, like other spray coatings, are mainly used to make a protective layer against corrosion.

Cement-based mortar coatings are used both as a restoration solution and to protect the structure and eliminate leaks. The application requires clean pipes, with removal of scale, knots, deposits, rust and other debris. For proper cleaning, you can also use very high pressure water jets, brushes, pigs, scrapers, and other mechanical equipment such as moles, cutters and root cutters. Some of these techniques can also be used together to obtain better cleaning and drying of the piping before applying the mortar.

Cement mortars provide two advantages. First of all, they are highly alkaline and offer protection against corrosion. Furthermore, the relatively smooth surface of the coating reduces roughness and improves the flow characteristics inside the pipe, also offering excellent internal protection.

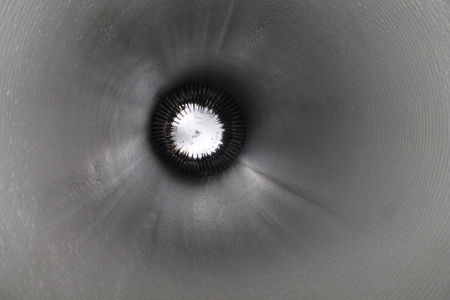

In pipes that cannot be walked on by humans, the mortar is sprayed with a special device with a rotating head by means of a pumping station on the surface that sends it through flexible pipes, or from a special feeding hopper. The thickness of the coating is determined by the speed with which the machine is pulled through the pipe. The application of the mortar is followed by a smoothing process, with a rotating spatula to be mounted on the sprayer or with a cone of the same internal diameter as the existing tube, to be connected behind the CML applicator so that it can tow it inside of the piping.

In tunnels and pipes that allow human entry, the mortars can be used to carry out totally or partially structural interventions with the addition of polymers or application of reinforcing steel fibers placed on the walls of existing tunnels and pipes.